SOLAVITE Oil&Gas cleans and maintains pipes, ducts and tanks free of organic deposits (paraffin, asphaltene and mixed) and minerals (barium sulfate, calcium carbonate, sodium chloride, etc.). SOLAVITE Oil&Gas removes existing organic and mineral scales besides preventing the formation of new ones in several systems of crude oil exploration and production, transportation and storage, completely eliminating the need for chemical, mechanical or thermal cleaning.

Benefits of SOLAVITE Oil & Gas Technology

Increased productivity and reduced costs with maintenance and scale treatment.

|

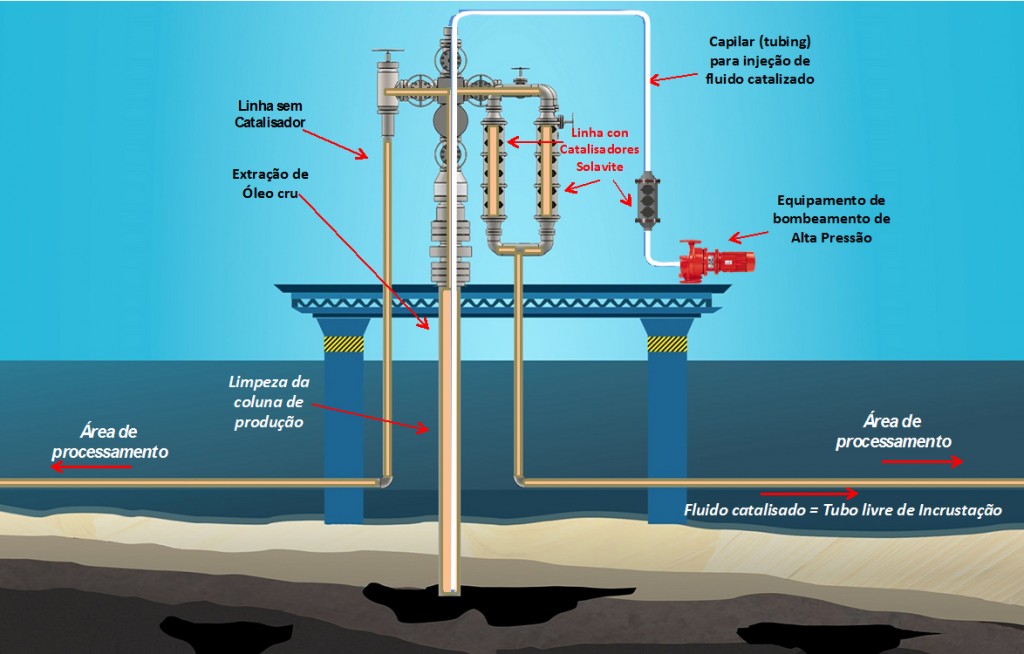

SOLAVITE Oil&Gas treats crude oil when it exits the wellhead by descaling its transport pipelines. To descale production pipes, part of the fluid catalyzed by SOLAVITE is re-injected through the casing pipe clearing and maintaining clear the production pipes and the wellhead.

Setup diagram of SOLAVITE in Platforms

Produced water extracted with crude oil must be re-injected into non-producing wells. The high salinity of waters rapidly causes scaling. SOLAVITE Oil & Gas treats the waste water to be re-injected into wells without using chemicals and at lower costs.

SOLAVITE Oil&Gas keeps pipelines clear without mechanical or chemical cleaning.

Solidification of crude oil and its by-products in storage tanks decreases the storage capacity of tanks. SOLAVITE Oil & Gas recirculation system installed in those tanks keeps them scale-free and increases their storage capacities.

Applying SOLAVITE Oil & Gas in boilers and cooling towers brings great economic and environmental benefits to Refineries and Petrochemical.